Deflection Gages (Deflectometers) – Model 3540

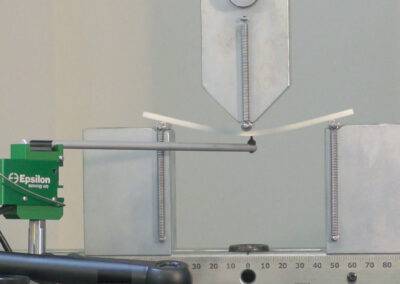

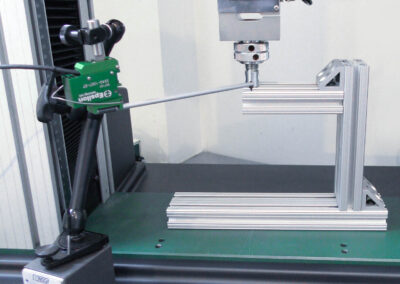

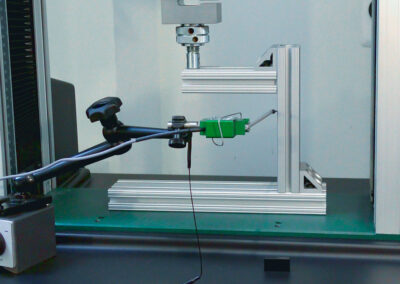

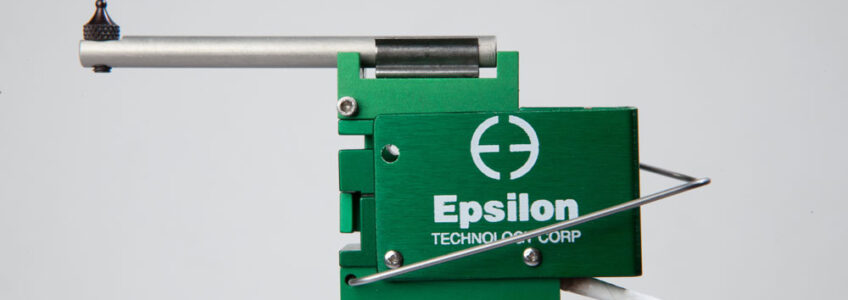

Deflection is measured with a single arm with an attached spherical contact tip, similar to those on a dial indicator. The full bridge strain gaged construction provides an electrical output compatible with any electronics designed for a strain gaged transducer.

The magnetic base furnished with the gage can be mounted to the desired reference surface, whether flat or round. The tip can then be positioned to measure the deformation encountered during the test. The magnetic base can only be used for low and standard temperature testing. Elevated temperature testing requires additional support considerations.

All models feature a spring loaded arm that can break free in the event of excessive displacement, protecting the deflection gauge from damage. The upper arm exerts a small spring force against the specimen, which is sufficient to allow dynamic cyclic testing if desired, yet light enough in force to avoid influence on the test. Because small variations in arm length can result in changes in the system calibration, the 3540 includes a mechanical stop for repeatable placement of the arm in situations where it becomes detached.

These units come standard with the arm set to measure downward deflections when oriented in the upright position. They can be used upside down or in any orientation. They may also be configured with the extensometer arm spring loaded downward. Specify this if desired. Note that the measuring ranges listed are total displacement.

The Model 3540 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller. The signal conditioning electronics for the extensometer is typically included with the test machine controller or may often be added. In this case the extensometer is shipped with the proper connector and wiring to plug directly into the electronics. For systems lacking the required electronics, Epsilon can provide a variety of solutions, allowing the extensometer output to be connected to data acquisition boards, chart recorders or other equipment.

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- Comes with an adjustable magnetic base for easy mounting.

- Spring loaded arm detaches to prevent damage from overtravel.

- Meets ASTM and ISO accuracy classes as follows.

- -001M, -004M, -006M, -005T, -015T, -025T:

ASTM E2309 Class A

ISO 9513 Class 1

ASTM E83 Class B-2 (assuming 50 mm gauge length per D790 and D6272) - -012M, -025M, -050M, -050T, -100T, -200T:

ASTM E2309 Class B

ISO 9513 Class 2

ASTM E83 Class C (assuming 50 mm gauge length per D790 and D6272)

- -001M, -004M, -006M, -005T, -015T, -025T:

- All standard units have linearity of 0.25% of FS or better.

- Includes the Epsilon Shunt Calibration System for on-site electrical calibration.

- Rugged, dual flexure design for improved performance.

- Includes high quality foam lined case.

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.

Output: 2 to 4 mV/V, nominal, depending on model

Linearity: ≤0.25% of full scale measuring range

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to 210°F)

Cable: Integral, ultra-flexible cable, 2.5 m (8 ft) standard

Operating Force:50 g typical

![]()

- Connectors to interface to nearly any brand of test equipment

- Arm orientation

Product Videos

Ordering Information

Click table options to configure

Gauge Length i

| mm or inches | # |

|---|---|

| 1.0 mm | -001M |

| 4.0 mm | -004M |

| 6.0 mm | -006M |

| 12.0 mm | -012M |

| 25.0 mm | -025M |

| 50.0 mm | -050M |

| 0.050 in | -005T |

| 0.150 in | -015T |

| 0.250 in | -025T |

| 0.500 in | -050T |

| 1.000 in | -100T |

| 2.000 in | -200T |

Selecting Extensometer Measuring Range

Measuring Range is the measuring capacity of the extensometer in tension (+) or compression (-) in units of % strain, maximum extension, or maximum deflection. When measuring range is in units of % strain, this means the maximum extension as a percentage of the gauge length.

Estimate the maximum strain or extension values you will need to measure, such as the total strain when the extensometer is removed after offset yield or the elongation at fracture. Then select a measuring range for the extensometer that meets or exceeds the requirements for the materials you are testing. If you are using a testing standard, also check the standard for extensometer requirements.

Temperature Range

| degrees | # |

|---|---|

| -270 ˚C to 100 ˚C (-454 ˚F to 210 ˚F) | -LT |

| -40 ˚C to 100 ˚C (-40 ˚F to 210 ˚F) | -ST |

| -40 ˚C to 150 ˚C (-40 ˚F to 300 ˚F)¹ | -HT1 |

| -40 ˚C to 200 ˚C (-40 ˚F to 400 ˚F)¹ | -HT2 |

| -270 ˚C to 200 ˚C (-454 ˚F to 400 ˚F)¹ | -LHT |

Model Number: 3540 – _ _ _ _ – _ _ _

Model3540 Available Versions: ANY combination of measuring range and temperature range listed above is available. Other configurations may be available with special order; please contact Epsilon to discuss your requirements.

¹Magnetic base not suitable for high temperature use; 50 °C (125 °F) max.

Example: 3540-012M-ST: 12.0 mm measuring range, standard temperature option (-40 °C to 100 °C)