High Temperature Self-Supporting Furnace Extensometers (1200 °C) – Model 3448

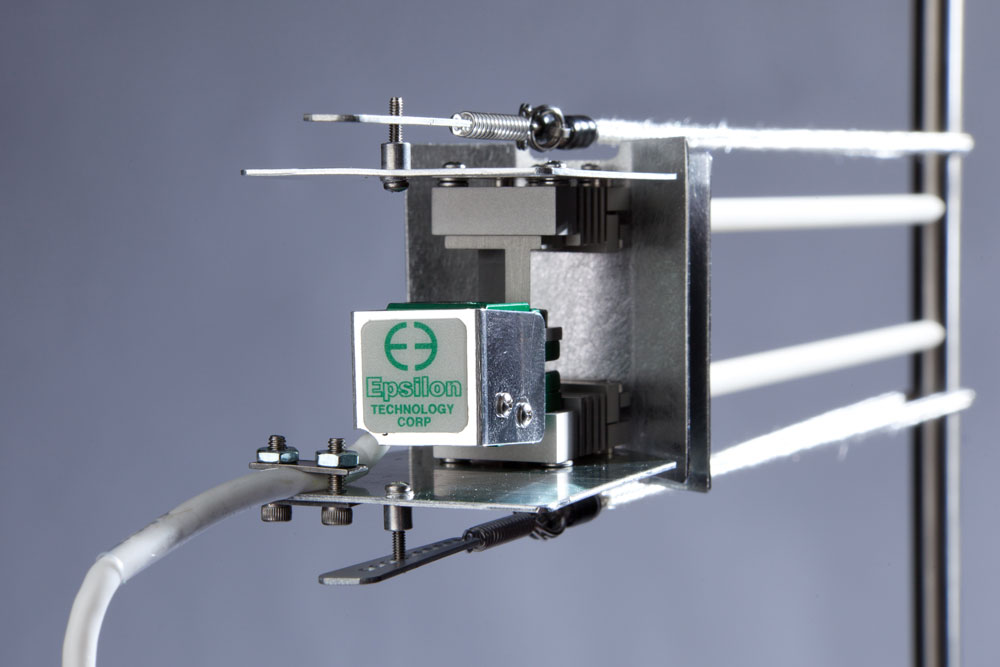

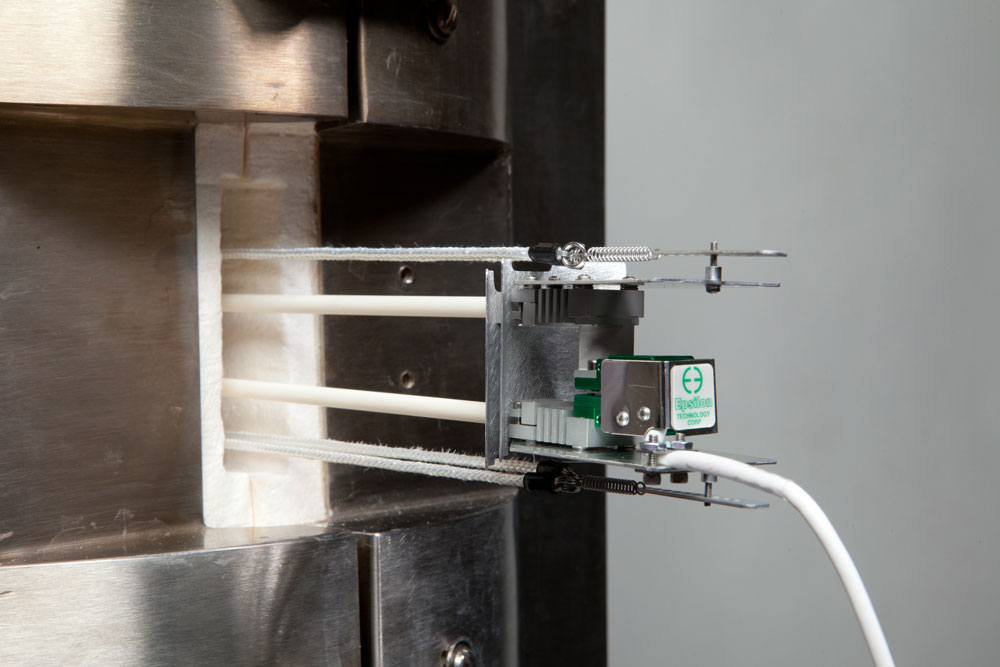

Epsilon developed this unique high temperature extensometer for testing metals, ceramics, and composites at the high temperatures produced by furnaces and induction heating systems. A combination of features make these extensometers easier to use and better in performance than other similar high temperature extensometers.

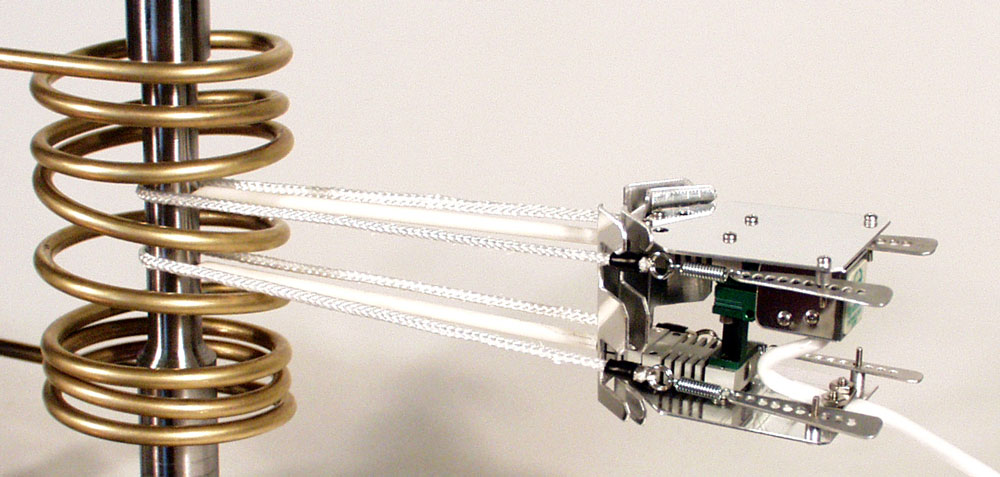

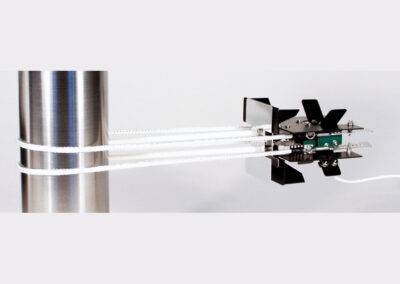

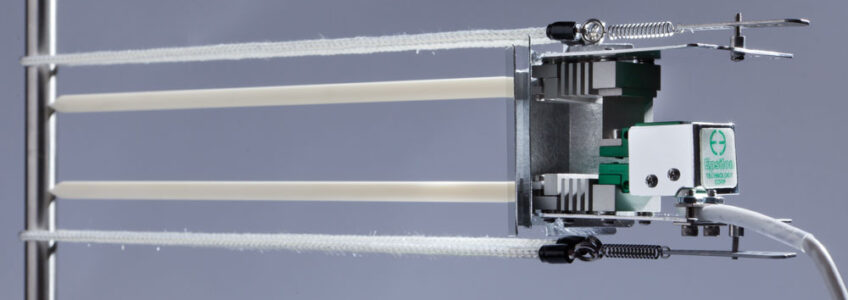

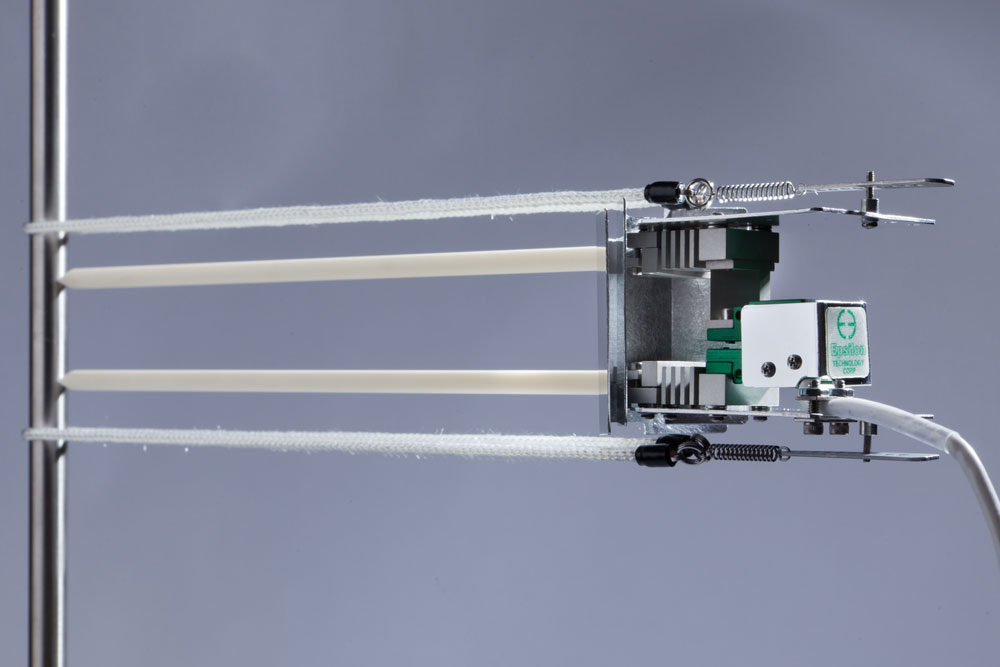

The units are held on the specimen by light, flexible ceramic fiber cords. These make the extensometer self-supporting on the specimen. No furnace mounting brackets are required. The side load on the test sample is greatly reduced because of the self-supporting design and light weight of the sensor. Most materials testing furnaces with a side cut-out for an extensometer will readily accept a Model 3448. For induction heating systems, a different ceramic cord placement allows the extensometer to easily pass between the coils.

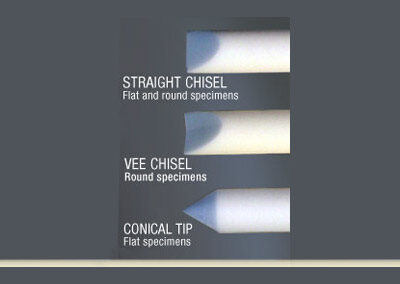

The combination of radiant heat shields and convection cooling fins allow this model to be used at specimen temperatures up to 1200 °C (2200 °F) without any cooling. An optional tiny air fan does enhance stability at the highest temperatures and is recommended for the highest accuracy and for tests with small elongations. The fan comes with a magnetic base for support so it can be mounted at any convenient location near the extensometer. Fan cooling is not generally needed for induction heated systems. High purity alumina ceramic rods are used. These are available in lengths as required to fit your furnace. A spare set is included with every extensometer. Specify chisel, vee chisel or conical contact points as desired.

Most units operate equally well in tension and compression. Tensile, compression and cyclic fatigue tests can all be performed with a single unit. For testing in strain control or to get the highest performance during cyclic fatigue tests, models 3549 or 7650A are recommended.

- May be left on through specimen failure.

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- Mechanical overtravel stops in both directions.

- All units come with high purity alumina ceramic rods.

- Mounts with flexible ceramic fiber cords. Very simple to install, this Epsilon exclusive design eliminates the need for external support brackets. Low contact force does not vary during testing like some externally supported extensometers.

- Use without cooling to 1200 °C (2200 °F). Optional small fan improves stability at highest temperatures.

- Versions available for use in vacuum and controlled atmospheres. Radiant heat transfer cooled versions are available for these applications.

- May be used on nearly any furnace with side entry cut-out for extensometers. Alternate configuration available for insertion between coils of induction heaters.

- Includes the Epsilon Shunt Calibration System for on-site electrical calibration.

- Rugged, dual flexure design for strength and improved performance.

- Includes high quality foam lined case, a spare set of ceramic rods, and eight ceramic fiber cords.

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.

Output: 2 to 4 mV/V, nominal, depending on model

Accuracy: Standard configurations meet ASTM E83 class B-1 and ISO 9513 class 0,5 requirements for accuracy. A test certificate is included. Rod lengths >250 mm (10″) can affect the final class rating.

Linearity: ≤0.15% of full scale measuring range, depending on model

Temperature Range: Ambient to 1200 °C max (2200 °F), all versions

Cable: Integral, ultra-flexible cable, 2.5 m (8 ft) standard

Contact Force: Adjustable, approximately 200 g depending on configuration

Operating Force:10 to 20 g typical

![]()

- Air cooling fan: add suffix -AC

- Ceramic cord orientation for furnaces or induction heaters (specify)

- Connectors to interface to nearly any brand of test equipment

- Rod tips can be straight chisels, conical tips or vee chisels; specify when ordering

Product Videos

Ordering Information

Click table options to configure

Gauge Length i

| mm or inches | # |

|---|---|

| 10.0 mm | -010M |

| 25.0 mm | -025M |

| 50.0 mm | -050M |

| 0.500 in | -0050 |

| 1.000 in | -0100 |

| 2.000 in | -0200 |

Selecting Extensometer Gauge Length

Extensometer Gauge Length is the distance between the extensometer’s initial measuring points on the specimen. If you are using a testing standard, check the standard for extensometer gauge length requirements. Many test standards specify the specimen dimensions and a matching extensometer gauge length.

Many specimens have a reduced section length that is designed to be greater than the extensometer’s gauge length.

Measuring Range i

| % strain | # |

|---|---|

| ±5% | -005¹ |

| ±10% | -010 |

| +20%/-10% | -020 |

| +50%/-10% | -050 |

| +100%/-10% | -100² |

Selecting Extensometer Measuring Range

Measuring Range is the measuring capacity of the extensometer in tension (+) or compression (-) in units of % strain, maximum extension, or maximum deflection. When measuring range is in units of % strain, this means the maximum extension as a percentage of the gauge length.

Estimate the maximum strain or extension values you will need to measure, such as the total strain when the extensometer is removed after offset yield or the elongation at fracture. Then select a measuring range for the extensometer that meets or exceeds the requirements for the materials you are testing. If you are using a testing standard, also check the standard for extensometer requirements.

Model Number: 3448 – _ _ _ _ – _ _ _

Model 3448 Available Versions: Any combination of gauge length and measuring range listed above is available, except as noted. Ceramic rod lengths are made to fit furnaces as required. Please provide furnace dimensions at the time of order. Other configurations may be available with special order; please contact Epsilon to discuss your requirements.

¹For 10 mm and 0.5 inch gauge lengths, the ±5% strain range is only available with short ceramic rods.

²Not available in 50 mm or 2.0 inch gauge lengths.

Example: 3448-0100-020: 1.000 inch gauge length, +20%/-10% measuring range, room temperature to 1200 °C