Miniature Axial Extensometers – Model 3442

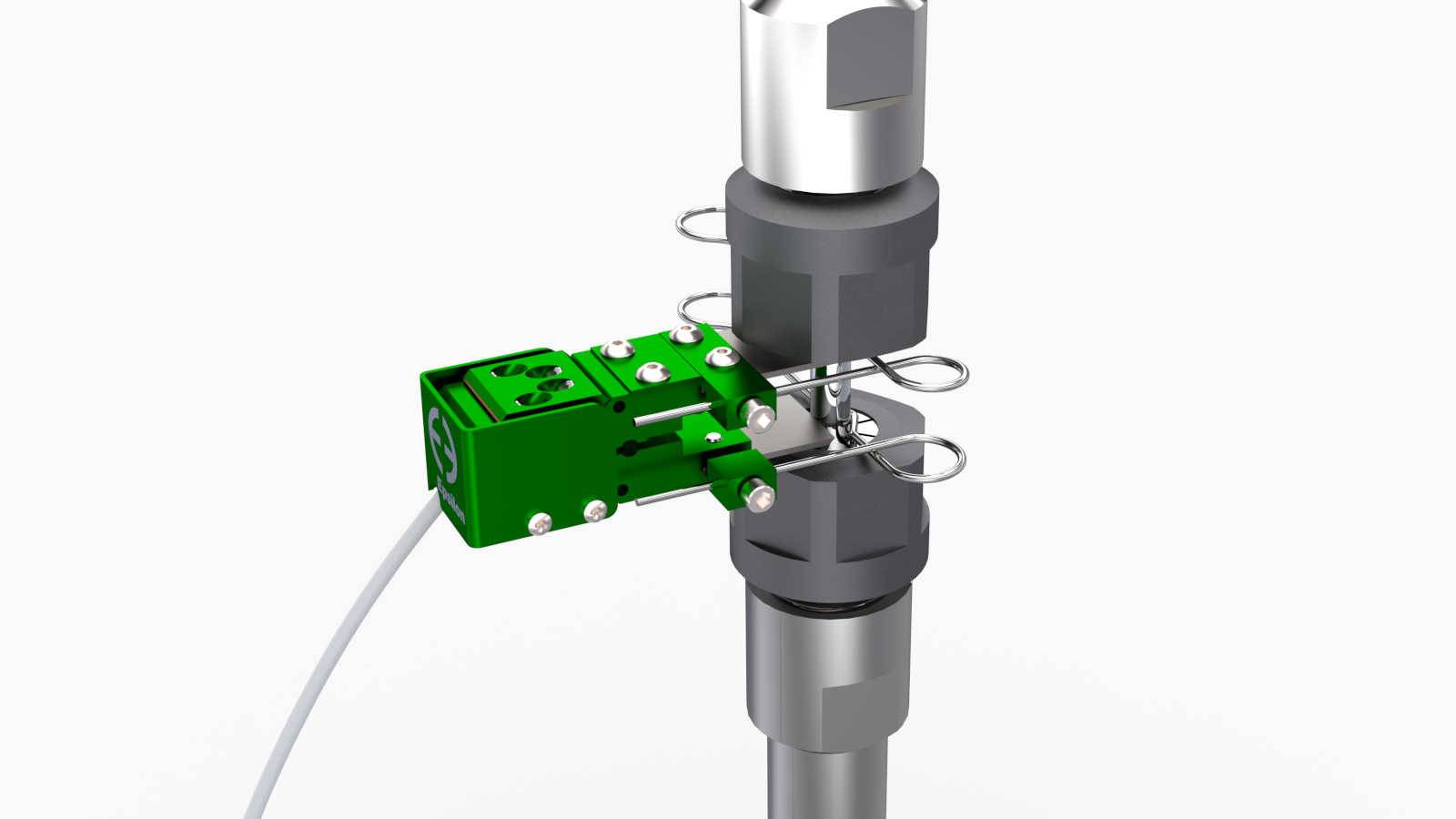

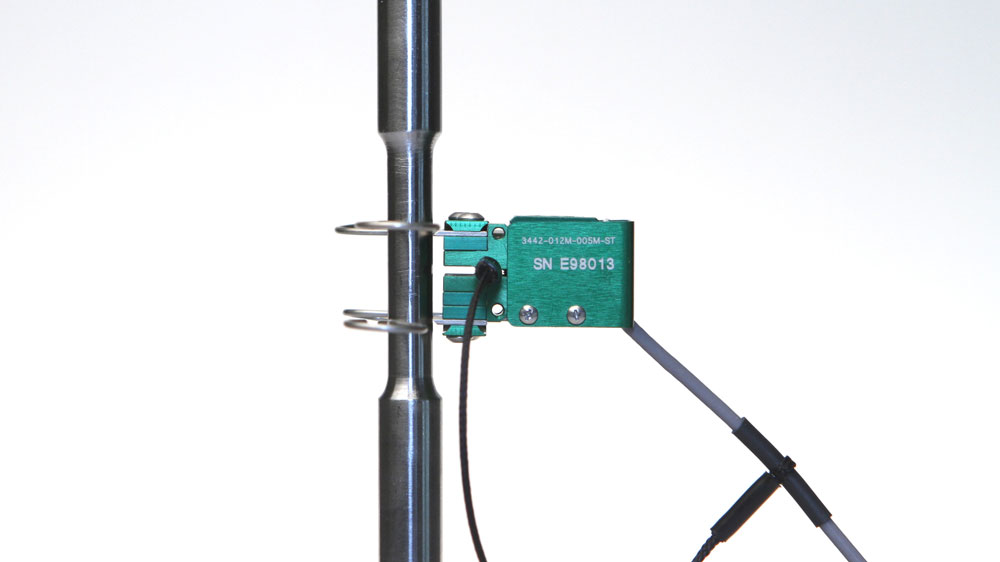

Weighing as little as 8 grams, these miniature extensometers are designed to have very low operating force with minimal specimen influence. Their low mass makes them the optimum choice for fatigue testing in strain control and high-frequency testing.

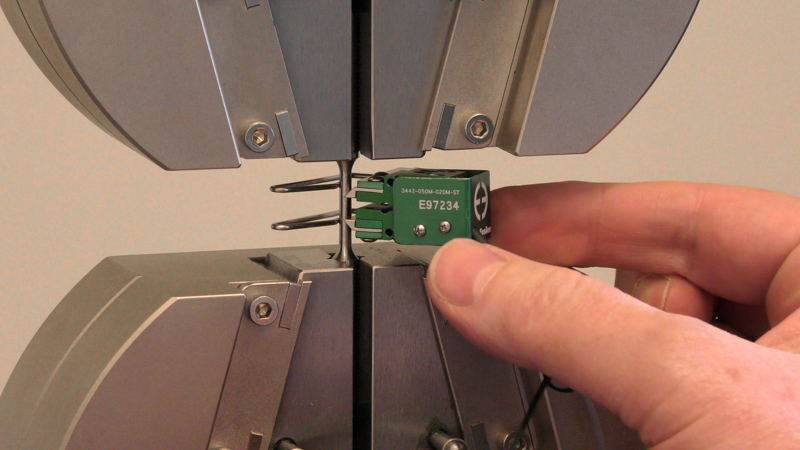

Suitable for tension or compression testing, all configurations use an improved version of Epsilon’s dual flexure design which makes them very rugged for their size. With a compact module that is 15.2 mm (0.6 inches) high, they will fit in the limited space between grips that is typical with small test samples.

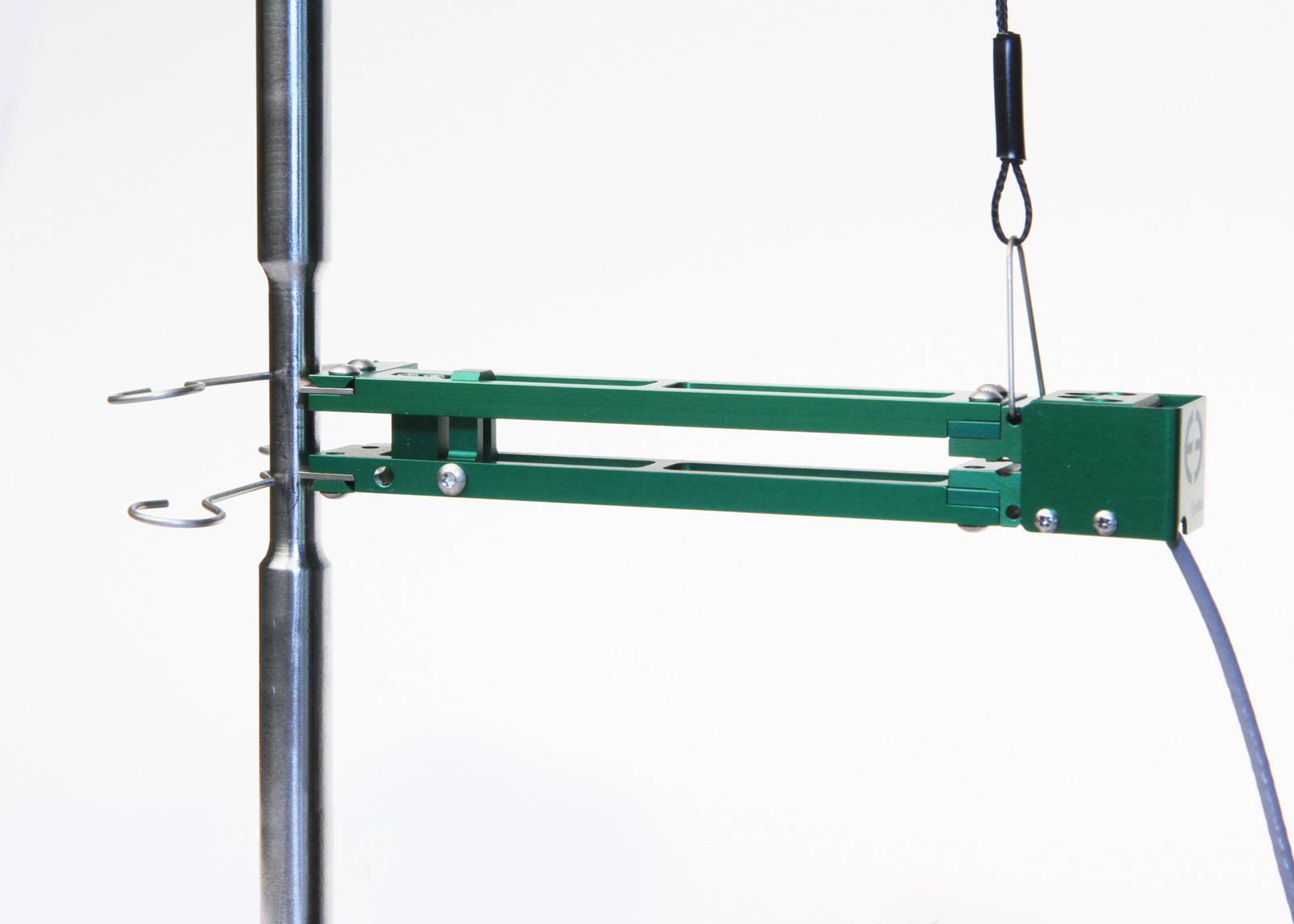

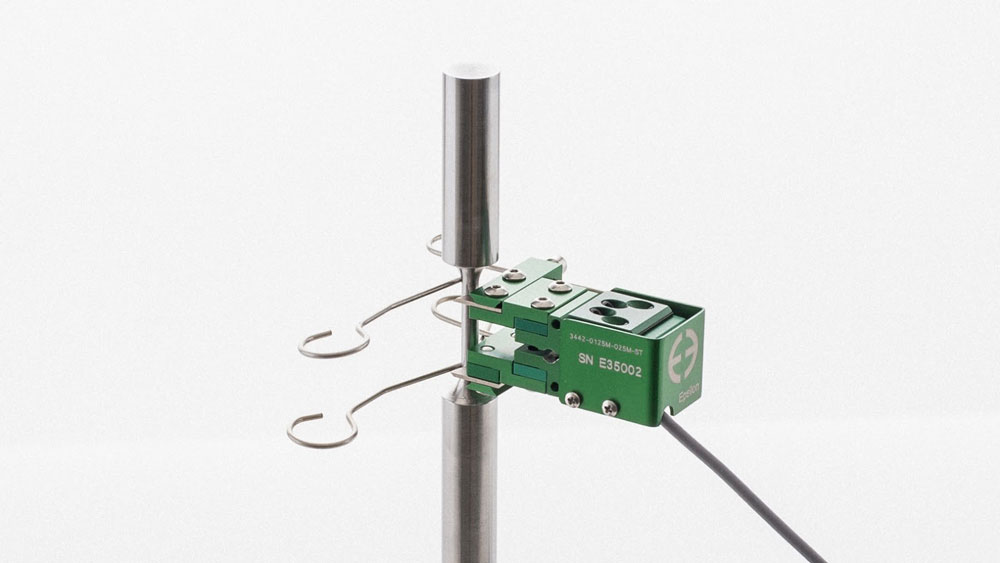

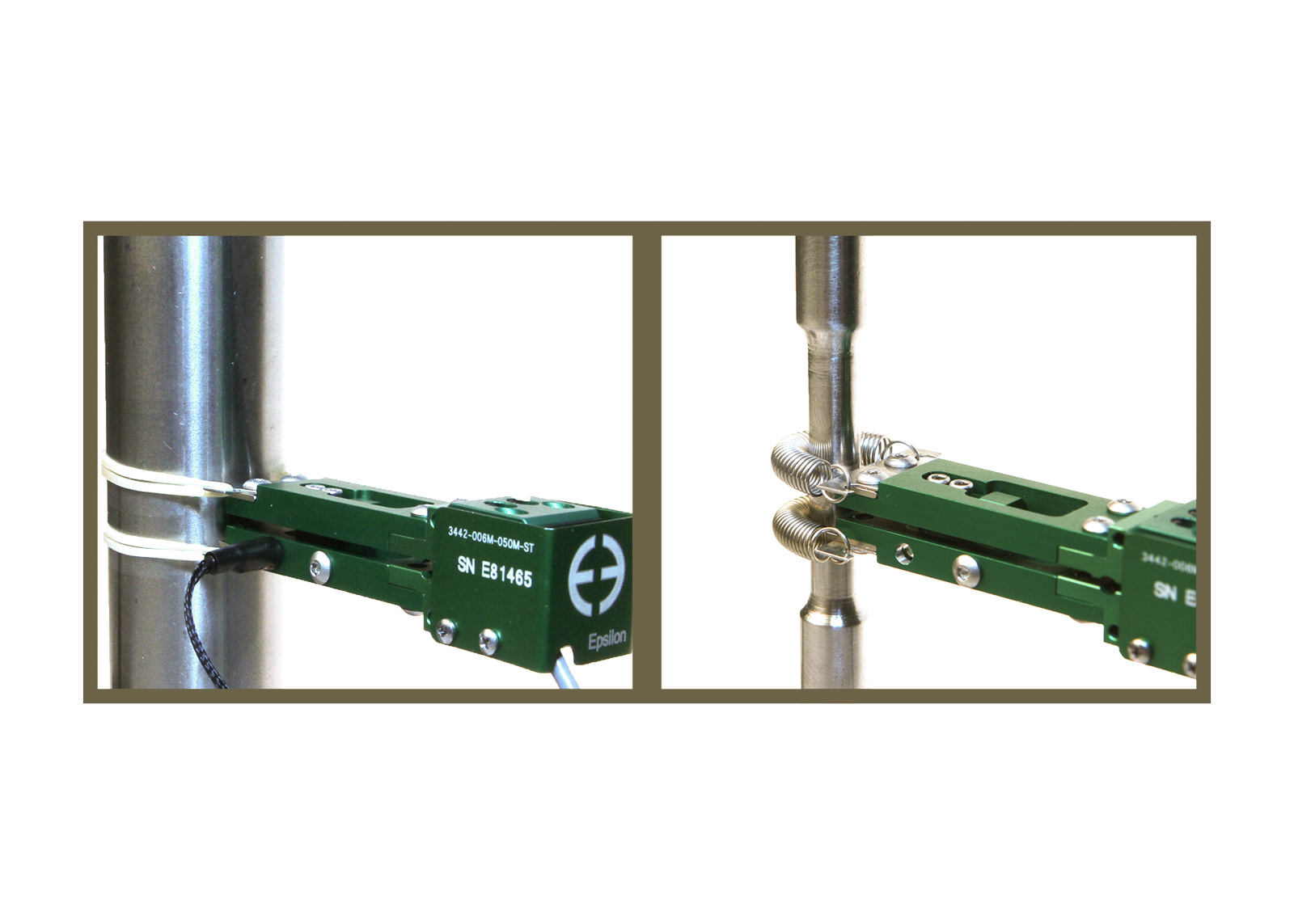

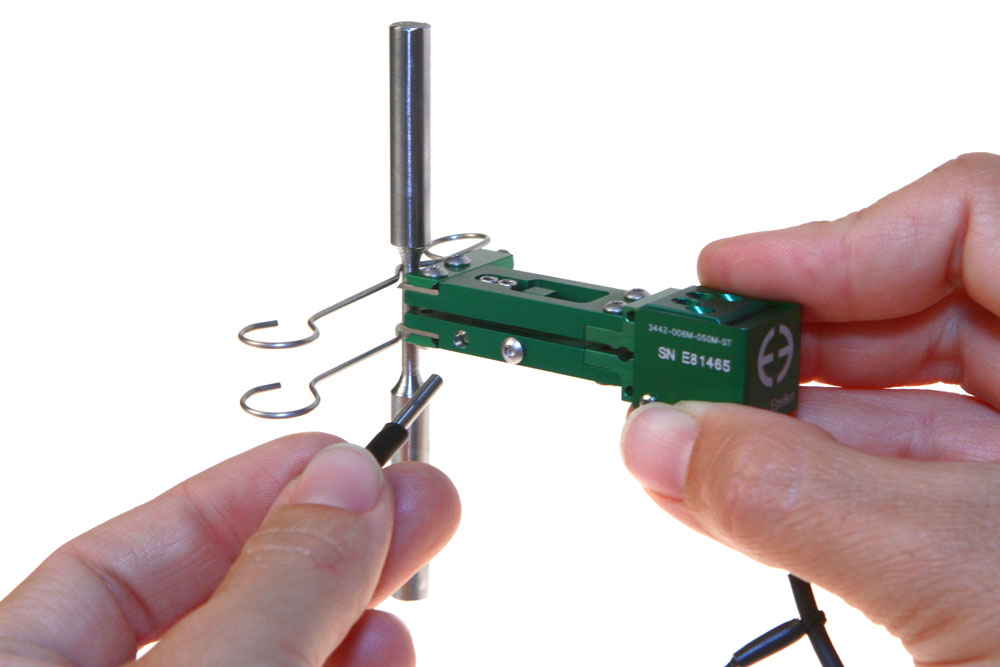

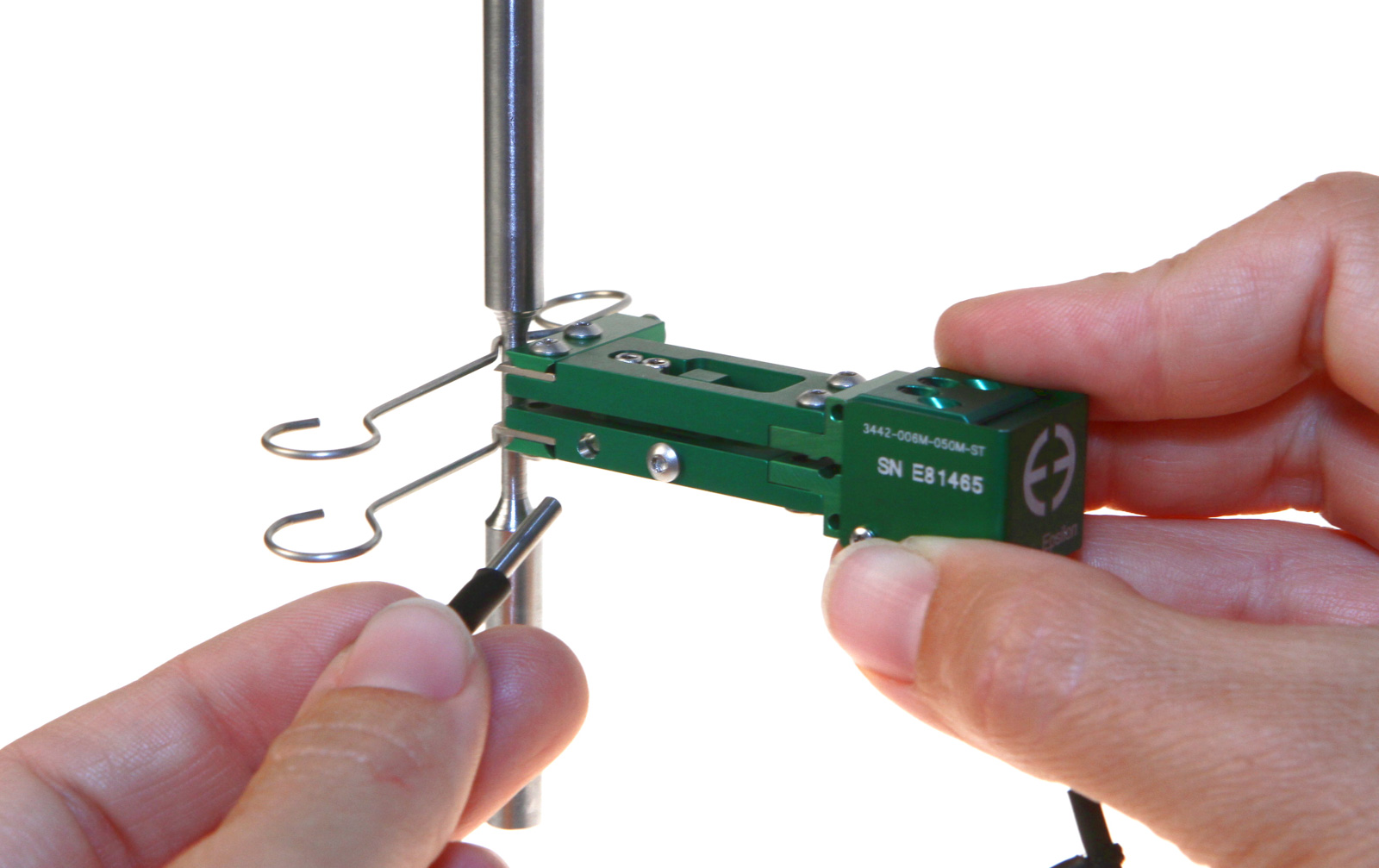

Gauge lengths can be as short as 3 mm or as long as 50 mm. A newly designed gage setting pin and assembly allows the gauge length to be set accurately and repeatably to ASTM and ISO requirements for all gauge lengths. Reengineered quick attach wire forms provide simple and secure specimen attachment. Wire forms for round and flat specimens are included, as well as knife edges in flat, 3-point, and vee configurations. The wire forms may be removed to enable mounting using elastic bands or springs. A tethering attachment point provides fall protection and enables counterbalancing of the extensometer’s weight when testing delicate specimens.

Model 3442 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller with electronics for a strain channel, and Epsilon will equip the extensometer with a compatible connector wired to plug directly into the controller. For systems lacking the required electronics, Epsilon can provide a variety of solutions for signal conditioning and connection to data acquisition systems or other equipment.

- May be left on through specimen failure in most applications i

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- Gauge length pin helps set gauge length accurately for all gauge length configurations.

- All models can measure in both tension and compression and can be used for cyclic testing.

- Mechanical overtravel stops in both directions.

- Rugged, dual flexure design for strength and improved performance. Much stronger than single flexure designs, this also allows cyclic testing at higher frequencies.

- Gauge length adapter kits enable configuration of multiple gauge lengths with one extensometer.

- Replaceable arms and spacers for ease of repair.

- High and low temperature options extend operation from as low as -270 °C to +200 °C (-454 °F to +400 °F).

- Includes the Epsilon Shunt Calibration System for on-site electrical calibration.

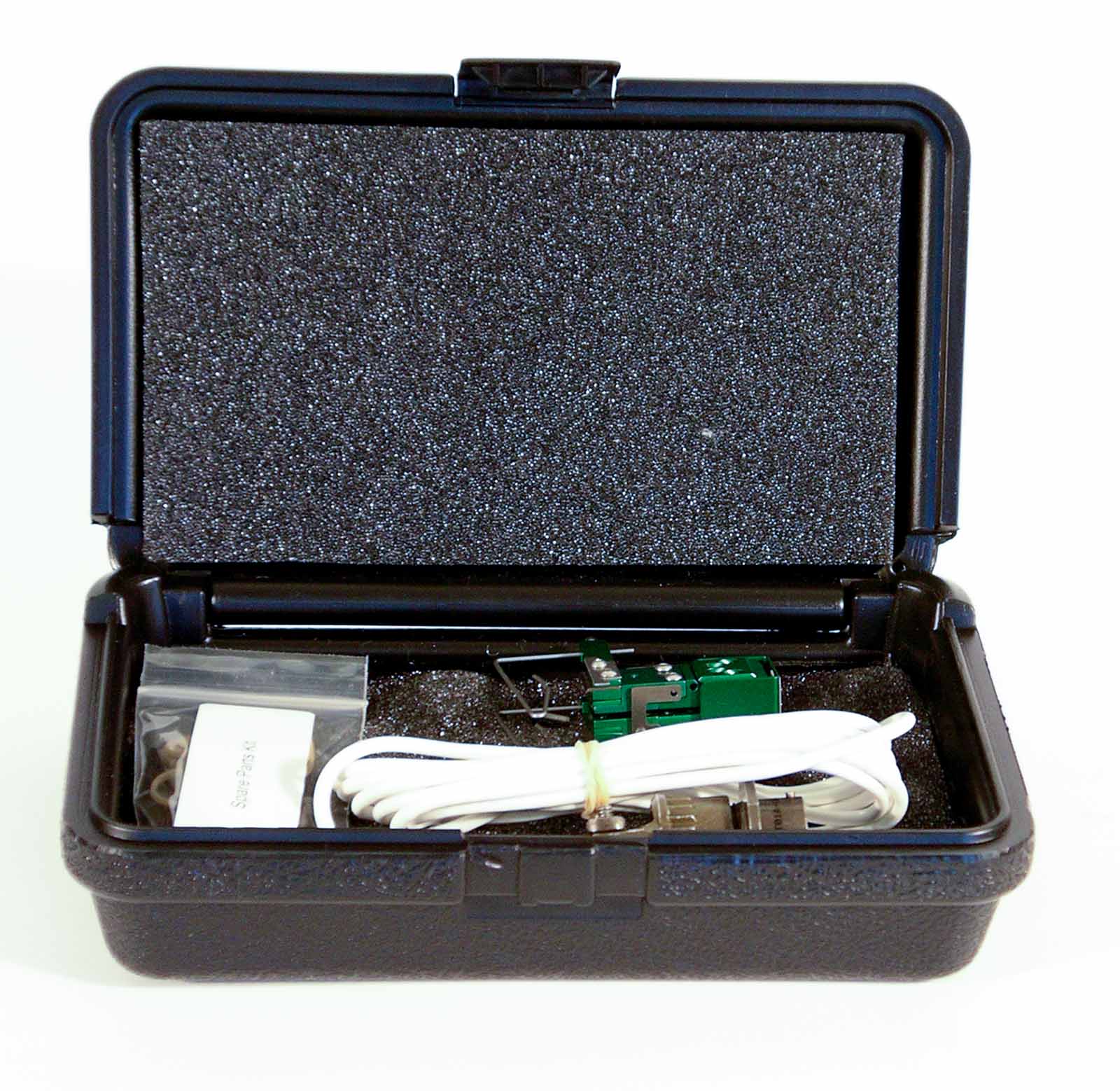

- Includes high quality foam lined case.

When does an extensometer have to be removed before specimen failure?

Remove model 3542 and 3442 extensometers before specimen failure, or use an Epsilon ONE® non-contacting extensometer, in the following applications:

- Rebar and other materials with textured or rough surface finishes (note: use model 3543 or Epsilon ONE to test rebar through failure)

- Wire cable

- Unidirectional composites and similar materials that explode / disintegrate at failure

- Non-rigid griping systems such as “lever action” wedge grips with moveable grip faces or grips with spherical seats

- Long samples of elastic material

- When the expected elongation of the material exceeds the extensometer’s measuring range (for example, using a 10% extensometer with a metal specimen that fails at 20% elongation)

- Rupture of internally pressurized specimens

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.

Output: 2 to 4 mV/V nominal, depending on model

Accuracy: Standard configurations meet ASTM E83 class B-1 accuracy requirements for gauge lengths ≥6 mm and class B-2 for ≤5 mm. All standard configurations meet ISO 9513 class 0,5. A test certificate is included.

Linearity: ≤0.15% of full scale measuring range

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to 210 °F)

Cable: Integral, ultra-flexible cable, 2.5 m (8 ft) standard

Standard Quick Attach Kit: Fits round samples 0.5-13 mm (0.02-0.5 inch) diameter and flats 0.1-13 mm thick by up to 15 mm wide (0.005-0.5 inch by up to 0.6 inch); attach to larger specimens using rubber bands or springs (included)

Operating Force: Depends on model configuration; 10 to 100 g typical

![]()

- Adapter kits to change gauge lengths

- Connectors to interface to nearly any brand of test equipment

- Special coatings and stainless steel knife edges available for biomedical tests

- Specialty Knife Edges

Product Videos

Ordering Information

Click table options to configure

Gauge Length i

| mm or inches | # |

|---|---|

| 3.0 mm | -003M¹ |

| 4.0 mm | -004M¹ |

| 5.0 mm | -005M¹ |

| 6.0 mm | -006M |

| 8.0 mm | -008M |

| 10.0 mm | -010M |

| 12.0 mm | -012M |

| 12.5 mm | -0125M |

| 20.0 mm | -020M |

| 25.0 mm | -025M |

| 50.0 mm | -050M |

| 0.250 in | -0025 |

| 0.300 in | -0030 |

| 0.500 in | -0050 |

| 0.640 in | -0064 |

| 1.000 in | -0100 |

| 2.000 in | -0200 |

Selecting Extensometer Gauge Length

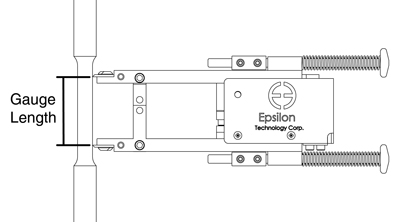

Extensometer Gauge Length is the distance between the extensometer’s initial measuring points on the specimen. If you are using a testing standard, check the standard for extensometer gauge length requirements. Many test standards specify the specimen dimensions and a matching extensometer gauge length.

Many specimens have a reduced section length that is designed to be greater than the extensometer’s gauge length.

Measuring Range i

| extension | # |

|---|---|

| ±0.5 mm | -005M |

| ±1.0 mm | -010M |

| +2.0 mm / -1.0 mm | -020M |

| +2.5 mm / -1.0 mm | -025M² |

| +5.0 mm / -1.0 mm | -050M² |

| +10.0 mm / -1.0 mm | -100M² |

| +12.5 mm / -1.0 mm | -125M² |

| ±0.050 in | -005T |

| +0.100 in / -0.050 in | -010T² |

| +0.250 in / -0.050 in | -025T² |

| +0.500 in / -0.050 in | -050T² |

Selecting Extensometer Measuring Range

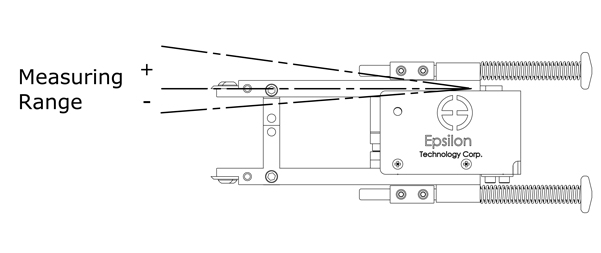

Measuring Range is the measuring capacity of the extensometer in tension (+) or compression (-) in units of % strain, maximum extension, or maximum deflection. When measuring range is in units of % strain, this means the maximum extension as a percentage of the gauge length.

Estimate the maximum strain or extension values you will need to measure, such as the total strain when the extensometer is removed after offset yield or the elongation at fracture. Then select a measuring range for the extensometer that meets or exceeds the requirements for the materials you are testing. If you are using a testing standard, also check the standard for extensometer requirements.

Temperature Range

| degrees | # |

|---|---|

| -270 °C to 100 °C (-454 °F to 210 °F) | -LT |

| -40 °C to 100 °C (-40 °F to 210 °F) | -ST |

| -40 °C to 150 °C (-40 °F to 300 °F) | -HT1 |

| -40 °C to 200 °C (-40 °F to 400 °F) | -HT2 |

| -270 °C to 200 °C (-454 °F to 400 °F) | -LHT |

Model Number: 3442 – _ _ _ _ – _ _ _ – _ _

Model 3442 Available Versions: ANY combination of gauge length, measuring range and temperature range listed above is available, except as noted. The measuring range should not exceed the gauge length. Other configurations may be available with special order; please contact Epsilon to discuss your requirements.

¹Available in -010M and -020M measuring ranges only; meets accuracy requirements for ASTM E83 class B-2. Gauge lengths of 6 mm or larger are recommended.

²Extended compressive measuring ranges are available – inquire with Epsilon.

Example: 3442-008M-010M-ST: 8 mm gauge length, ±1.0 mm measuring range, standard temperature range (-40 °C to 100 °C)